Virtual Reality in Industry: Main uses, benefits and outstanding examples

The digital transformation is advancing by leaps and bounds, and the Virtual Reality has become a key tool for companies seeking to improve the quality of their products and services. innovate, optimize processes and improve safety in their operations. From industrial process simulation to advanced training and remote maintenance, VR is redefining the way companies work, reducing costs and maximizing efficiency.

In this article, we will explore the main Virtual Reality applications in the industryits key benefits and success stories developed by Imascono. Find out how companies in a variety of industries are already using this technology to train their employees. more effectively. Minimizing risks and accelerating your innovation processes.

Are you ready to take the leap and revolutionize your training process? Read on and find out.

Impact of Virtual Reality on the industry

The Virtual Reality technology has ceased to be just an entertainment technology and has become a transformative tool in the industry. From manufacturing to vocational training, Virtual Reality (VR) is redefining the way companies design, operate and train their teams..

Companies that have adopted the experience of Virtual Reality not only have they optimized their processes, but they have also reduced costs, improved safety and enhanced efficiency. Allowing to simulate real work environments with an impressive level of accuracy, offering immersive experiences that increase productivity and innovation. In addition, these VR experiences help to deepen training and prevention in occupational hazards, by developing simulations of risky environments where professionals can practice and train; as in the case of the Global Spedition Virtual Training.

In sectors such as automotivethe constructionthe health and logistics, Virtual Reality is driving an unprecedented digital revolution and generating a direct impact on their competitiveness. The result? Fewer mistakes, greater safety and more effective learning.

If you are interested, here you can find out more about the benefits of VR training in factories

Main applications of Virtual Reality in the industry

The Virtual Reality has opened up a world of possibilities in the industrial sector, transforming processes, optimizing operations and raising efficiency to unprecedented levels. Below, we explore the most impactful applications of this technology that is revolutionizing the industry.

Simulations in industrial processes

Factories and production plants are integrating Virtual Reality to simulate complete industrial processes prior to actual implementation. The benefit? Reduction of errors, time optimization and less waste of materials, especially in the early stages of training. Thanks to Virtual Reality, factory engineers, for example, can visualize and test assembly lines, detect faults before they occur and improve efficiency without stopping production.

You can continue reading about the training and simulations at Simulation learning positions itself as a key model in high-risk environments

Training and education

Training in industrial environments often involves risks and high costs. Especially if there is a clear opportunity cost (if I dedicate machine hours to training and not to production). Virtual Reality allows you to train employees in a safe environment, without endangering their integrity or the machinery..

In addition to giving them more time for trial and error (they can do the virtual training as many times as they need) without having to use the real machine or product, at least in the early stages of training. The result: a faster learning, reduced accidents and improved retention of knowledge.

Learn about all the benefits of this type of training → Virtual Training: virtualized training and simulations

Remote equipment maintenance

Thanks to the Virtual Realitytechnicians can receive real-time assistance from anywhere in the world for troubleshooting in industrial machinery and equipment. This minimizes downtime, reduces costs and allows a quick response to critical breakdowns. Using Virtual Reality to guide operators in maintenance without the need to send experts to the site, optimizing time and resources.

Product design

Virtual Reality has revolutionized product development by enabling the creation of fully interactive virtual prototypes. Companies can visualize and modify designs in a 3D environment before physically manufacturing a single component, saving time and money unnecessary iterations. This is also an advantage at the customer level, since it allows them to customize their products and, above all, to be able to see them virtually before they are finished. This helps to better understand their utilities and advantages, as well as facilitating a greater connection.

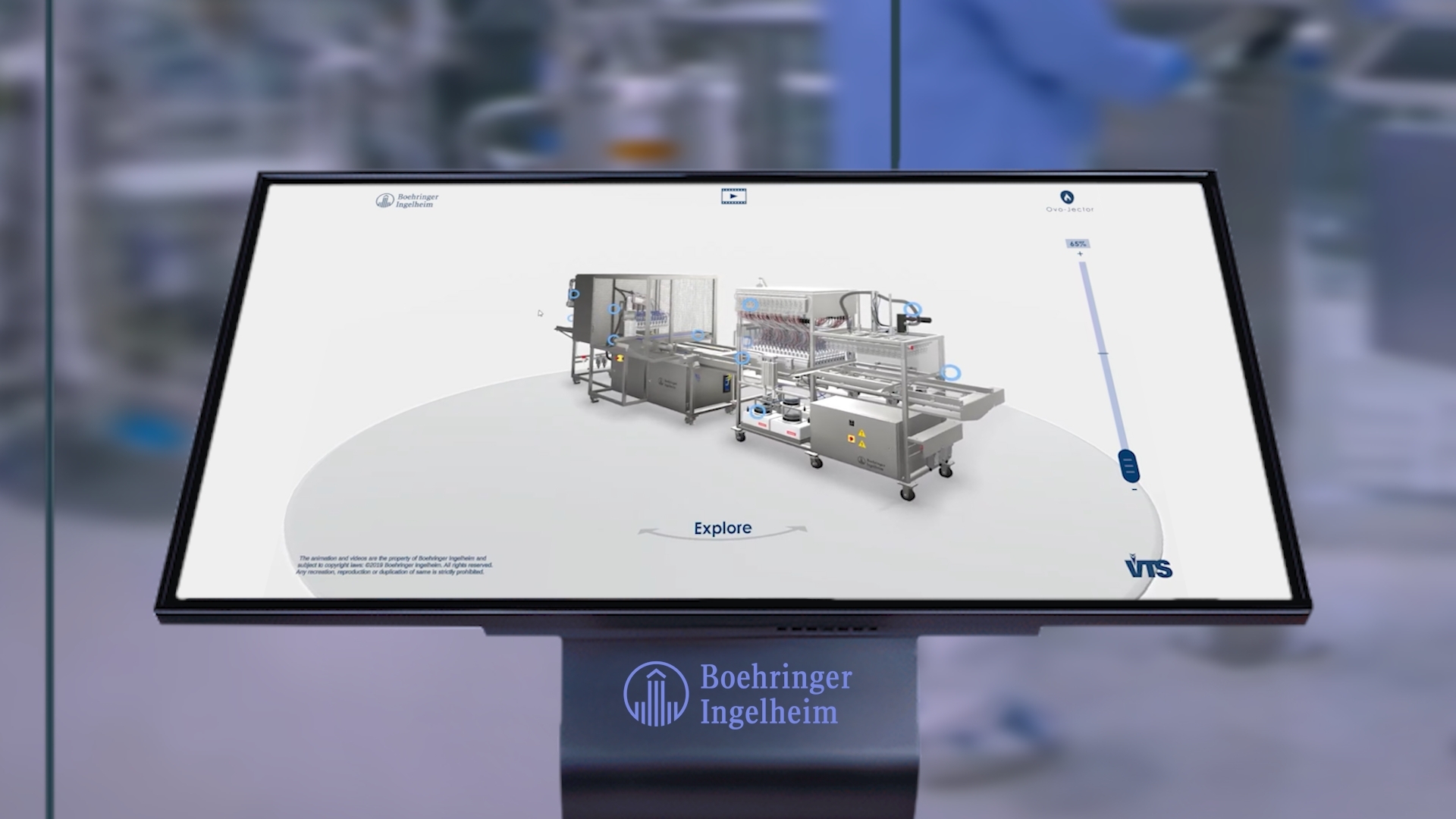

An example of this can be found in the Boehringer Ingelheim's virtual proposal for the commercialization of your oviparous machine OVO Xtractor. That in addition to having a version interactive infographichad his experience in Virtual Reality.

Key benefits of Virtual Reality in the industry

Investing in Virtual Reality in the industrial sector is not just a commitment to innovation, is a strategy to improve efficiency, reduce costs and increase safety in industrial environments.. Next, we explore the three key benefits that make VR an indispensable tool in the industry.

Improved safety

The industry is full of dangerous environments where a mistake can be costly. Virtual Trainings allow workers to be trained in hazardous conditions without exposing them to real hazards.

- Simulation of emergencies: Training in critical situations without physical risk to personnel.

- Occupational Risk Prevention: Increased preparedness to operate machinery or react to unforeseen events. Taking OHS training to new levels of immersion and realism.

- Controlled environments: Possibility to test procedures or new action plans in virtual simulations before applying them in the real world.

These virtual training can be applied to all types of sectors, but, in their commitment to safety, they are most important in the industrial sectors. From automotive to manufacturing, including construction and foodstuffs.

Process and time optimization

In the industry, time is moneyVirtual Reality helps to optimize it like no other technology. How? Enabling rapid design iterations and streamlining decision making.

- Accelerated prototyping: Test and adjust designs without the need to physically manufacture each version. In addition, designs can be customized in real time within the immersive experience, which also helps to focus on every detail.

- Faster training: Employees learn in immersive environments, reducing training time by eliminating all outside stimuli. You focus your senses of sight, hearing and touch (if gloves and haptic suits are included) on the VR simulation itself.

Cost reduction

Implementing new processes, training employees or designing products from the ground up can be costly and risky. With the Virtual Realitycompanies can test, train and experiment in virtual environments before investing in physical resources.

- Fewer errors: Thanks to simulations, fed by the entire database generated by IoT sensors, it is possible to have a virtual twin with which to identify or learn to identify faults before they happen in reality.

- Less wasted material: When it comes to training professionals in the industrial sector, training them in VR experiences helps to reduce the consumption of physical resources, either machinery or the manufactured products themselves, during the early stages of learning. Studies show that through VR training people learn 4 times faster (PwC).

- Less travel: Access to remote training and assistance without travel expenses, trainers or translators in different languages.

A success story in this regard is the Vaccines virtual training process developed by the international pharmaceutical company Boehringer Ingelheim. Through its virtual laboratory, healthcare workers from all over the world could learn the preparation process of its latest liquid medicine in more than 7 languages and as many times as they needed thanks to its VR training.

Examples of Virtual Reality in the industry highlighted by Imascono

At Imascono we have positioned ourselves as one of the technology companies with the longest active years working on VR experiences in the industrial sector. Together with companies such as Siemens, Moeve, Certest, Boehringer Ingelheim, IVECO, CEVA, Iberdrola or Telefónica, we have developed innovative projects that transform the training, safety and operational efficiency of their teams. Below are some of the most emblematic cases:

💉Vaccines Boehringer Ingelheim: Revolutionizing Pharmaceutical Training

Boehringer Ingelheim, one of the world's leading pharmaceutical companies, collaborated with Imascono to develop a program of Virtual Reality training The aim is to instruct healthcare professionals in the process of preparing their new injectable product.

This immersive experience allows users to familiarize themselves with each step of the procedure, ensuring thorough understanding and accurate execution with no associated risks. The The result is more effective, safe and efficient training.The product can be used in real environments.

🛡 Global Spedition: Elevating Occupational Risk Prevention

The logistics company Global Spedition took occupational risk prevention to the next level through an experience of Virtual Reality developed by Imascono. This immersive solution immerses employees into realistic scenarios where they can identify and manage potential hazards without exposing yourself to real risks.

By practicing in a controlled environment, workers acquire skills critical to workplace safety, significantly reducing the incidence of accidents and promoting a safety culture proactive within the organization.

🐄 Ceva Velactis: Innovation in Veterinary Training

CEVA, leader in the veterinary pharmaceutical industrypartnered with Imascono to create a immersive simulation highlighting the uses and benefits of Velactis, your new product. This experience of Virtual Reality enables veterinary professionals to interact with a wide range of virtual environment that replicates real clinical situations. Facilitating a thorough understanding of product application and benefits. The resulting training is more dynamic and effective, improving knowledge retention and ensuring optimal application.

At Imascono, we create immersive experiences that transform the industry, optimizing processes, improving safety and taking training to a new level. If you are ready to innovate and differentiate yourself with customized VR solutions, contact us today and we will help you as much as possible.