Simulation and virtual reality in the industrial sector: Use cases

In an increasingly dynamic and competitive industrial world, simulation and virtual reality have become essential allies in revolutionizing the way companies design, train, operate and communicate.. In this blog you will discover how immersive technologies are transforming key sectors, raising efficiency, safety and innovation to unprecedented levels. Through real case studies and pioneering projects from Imascono, you will learn how industry leaders such as IVECO, Tenías Group, Certest and Global Spedition are leveraging virtual simulators, digital twins and virtual reality training to drive their processes and position themselves as leaders in their markets. Get ready to explore the industrial future, where the virtual becomes the engine of real success..

Transforming the industrial sector with immersive technologies

The industrial sector is undergoing an unprecedented transformation thanks to the adoption of immersive technologies such as virtual reality, simulation and artificial intelligence. These tools allow create realistic digital environments to train employees, simulate critical processes or design products more efficiently and safely. This is a key evolution within the Industry 4.0 concept, which seeks greater flexibility, sustainability and operational precision.

The industrial simulators and digital twins facilitate remote collaboration and decision making, connecting global teams in intelligent virtual spaces. This breakthrough positions companies within the Industry 4.0, where digitalization and sustainability combine to improve competitiveness. Adopting these immersive technologies is no longer an option, but a necessity to innovate, reduce errors and lead in an industrial market.

You can learn more about the Industry 4.0 and its main characteristics in our blog post: https://imascono.com/que-es-industria-4-0/

Want to learn more about how technology is driving the industrial sector?

Key applications of simulation and virtual reality in industrial environments

The advent of virtual simulators and extended reality is revolutionizing many areas of the industrial sector. From specialized training to predictive maintenance, these technologies are helping to optimize processes, minimize risks and accelerate innovation. Below, we explore the most impactful applications.

Immersive technical training for operators and technicians

Training operators and technicians with immersive virtual simulators is much more than a simple training, it is a realistic and safe experience that allows you to practice complex tasks without real risks. With virtual environments that replicate machinery and industrial scenarios, technical training becomes more effective, intuitive and scalable. Operators can deal with emergency or critical maintenance situations, gaining confidence and skill without stopping production.

Simulation of processes and work environments

Industrial simulators allow recreate production lines, logistic flows and work environments to test and optimize each step before implementing it in reality. This virtual testing capability reduces prototyping costs and eliminates common errors in the design phase, accelerating innovation and improving operational efficiency. Companies in sectors such as automotive, energy and manufacturing are already betting on digital twins and virtual simulators to maximize results.

Predictive maintenance and support

Thanks to the virtual reality and artificial intelligence, maintenance tasks can anticipate potential failures by means of industrial simulators that identify hazards and guide repairs. In addition, remote assistance in 3D virtual environments connects expert technicians and operators in real time, facilitating the resolution of complex incidents without the need for travel.

Customer feedback

Immersive technologies have changed the dialogue with customers and industry partners. Collaborative virtual spaces allow to present prototypes, perform product tests and collect feedback in real time, optimizing design and adapting solutions to specific needs.. This digital interaction opens up new avenues for open innovation and customization of industrial offerings.

Avatars for process and corporate culture training

The virtual avatars with AI help to manage and integrate the operational and corporate communication to workers in a fast and efficient manner, solving doubts about industrial processes as well as about the company's own culture., all in real time, both offline and online, generating a lasting impact and improving staff engagement.

Want to learn more about how technology is driving the industrial sector?

Strategic benefits of adopting these technologies in industry

The incorporation of virtual simulators and immersive technologies in the industry not only represents a operational improvement, but a real competitive advantage. These tools transform traditional processes into digital experiences that drive productivity, safety and innovation.

Improved security: Thanks to industrial simulators, companies can train their personnel in safe and controlled environments, minimizing accidents and reducing risks in critical tasks. Immersive training makes it possible to practice emergency situations without endangering anyone.

Resource optimization: Simulating processes and environments before implementation avoids costly errors, reduces downtime and maximizes the efficient use of materials and machinery. Increasing savings and process agility.

Improved knowledge transfer: Virtual simulators facilitate hands-on, immersive training that improves knowledge retention and assimilation. Operators are better prepared, which is reflected in more accurate and efficient execution.

Collaboration and global connectivity: Immersive solutions allow geographically dispersed teams to connect in shared virtual spaces, enhancing cooperation, joint decision-making and open innovation.

Strengthening of the brand image: Implementing this type of technology positions the company as an innovative benchmark committed to technological excellence and labor responsibility, reflecting values aligned with sustainability by minimizing the use of physical resources. This combination of innovation and commitment strengthens the trust of customers and employees, enhancing the brand's reputation.

Main technological applications in industry

These technologies are demonstrating a real and measurable impact on industry, as evidenced by the following projects developed for industry leaders. These initiatives reflect how their applications have redefined different processes within industrial companies.

IVECO, a leader in commercial vehicles, was looking for improving training and internal communication for its thousands of employees. Together with Imascono, created IRIA, a avatar with artificial intelligence that centralizes access to training and consultations. IRIA provides fast and autonomous responses, enhancing the user experience. The internal team monitors its use to continuously optimize the platform. This project demonstrates the power of AI to transform industrial knowledge management.

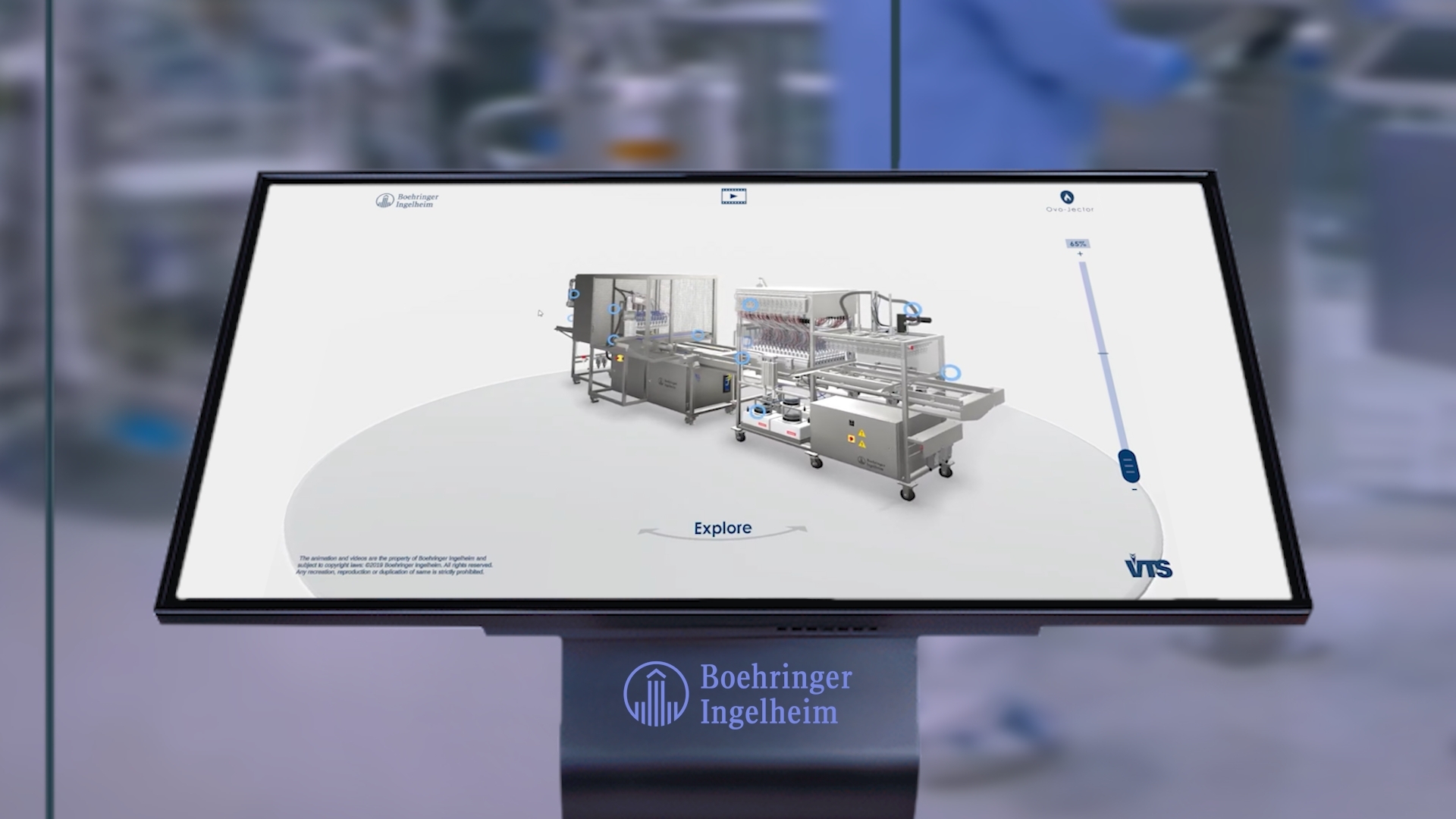

Grupo Tenías, a leader in agricultural machinery, needed an innovative way to showcase its products without relying on physical transportation. Imascono developed a Virtual Twin with interactive 3D design that allows 360º demos of your machines. This solution facilitates understanding and enhances the experience commercial. In addition, reduces logistical costs and accelerates sales. Thus, Grupo Tenías takes a digital leap in its commercial strategy.

Certest, a biotechnology company in expansion, sought to showcase its new facilities globally. Imascono developed an interactive virtual twin that replicates in detail its buildings and production lines. The virtual tour is accessible from cell phones and tablets, The twin is updated in real time by means of a real-time twin display. In addition, the twin is updated in real time through a Custom CMS. Thus, Certest connect with customers and partners in an innovative and efficient way.

Global Spedition, with extensive experience in hazardous materials transportation, needed to improve the safety training of its employees. Imascono created immersive virtual reality training, converting traditional manuals into gamified experiences. This solution allowed a faster and more effective learning in safe environments. The employees appreciated the training as useful and entertaining. Thus, Global Spedition reinforces its protocols with innovation and efficiency.

Want to bring simulation and virtual reality to your industry? At Imascono we have the experience and technology to transform your processes and enhance your innovation. Contact with us and find out how we can help you make it happen.